Search This Supplers Products:Refrigerated air dryerDesiccant air dryerWater chillerHeat recovery systemAdsorption air dryerAir filter

Heated regeneration adsorption air dryer supplier

- group name

- Desiccant air dryer

- Min Order

- 1 unit

- brand name

- SHANLI

- model

- SLAD-15MXF

- Nearest port for product export

- Ningbo, Shanghai, Guangzhou, Tianjin

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, Express Delivery

- Acceptable payment methods

- T/T, L/C, Cash

- update time

- Thu, 25 Dec 2025 18:58:55 GMT

Paramtents

Air inlet temp 20-45°C

Oil Content <=0.1PPM

Air consumption <=7%

Pressure dew point -40°C

Air inlet pressure 0.6~1.0MPa

Pressure loss ≤3% of inlet pressure

Place of origin Hangzhou, China

Certification CE CCC ISO9001

Power AC 380V-50HZ/ AC220V-50HZ

Warranty 1 year

Packging & Delivery

- 174cm x73cm x235cm

-

Min Order1 unit

Briefing

Detailed

Email:jovelyzou..........com

website: ..........com

Information for Heated regeneration adsorption air dryer supplier

● Regenerative desiccant dryers use desiccant media to dry compressed air through the process of adsorption.

● Dry air with dew points of either -20°C, -30°C, or -40°C can be achieved.

● These extremely low dew points are necessary in critical compressed air applications or for those in extremely cold environments

● In such environments, any moisture remaining in the air would freeze inside compressed air system piping, resulting in blocked flow.

Technical Specifications for Heated regeneration adsorption air dryer

● Max air inlet temp.: 45 Deg C

● Max air inlet pressure.:0.6-1.0 Mpa

● Air consumption: <=7% of inlet air

● Pressure loss; <=3% of inlet pressure

● Oil content: <=0.1PPM

● Pressure dew point: -40 Deg C (standard type)

● Control method: PLC control

● Power: AC 380V/220V-50HZ

● Cycling time: T=2 h

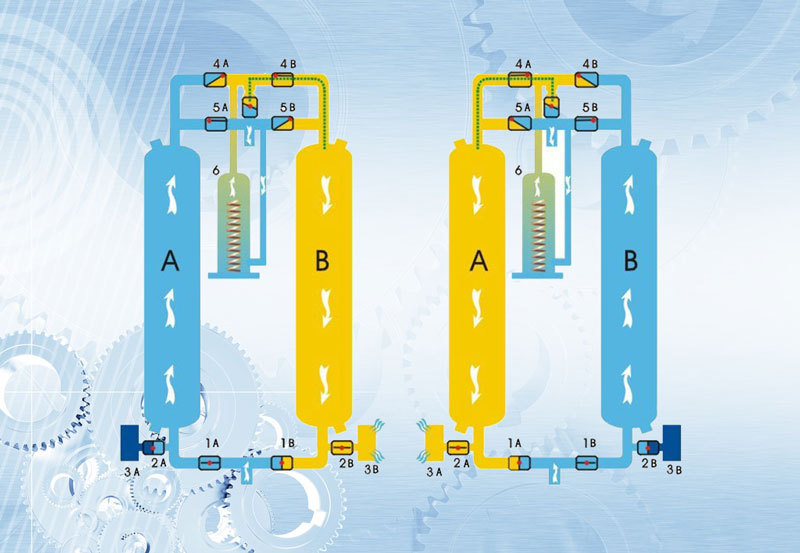

Working Principle

● During dryer operation, the desiccant media is used to dry the air followed by a period of regeneration when the media is purged of the moisture it collects so it can be used again for drying.

● Twin-tower design of our dryers allows simultaneous air drying and desiccant regeneration-without interruption of compressed air flow.

Note:

| 1. Gas inlet valve | 2. Gas drain valve | 3. Silencer |

|---|---|---|

| 4. Regenerative one-way valve | 3. Gas outlet one-way valve | A.B. Adsorptive tower |

Performance Parameters

Heated regeneration adsorption air dryer supplier

| Model | Air Capacity |

Desiccant Weight (Kg) |

Air Pipe Diameter |

Net Weight (Kg) |

Length (mm) |

Width (mm) |

Height (mm) |

|

| (Nm3/min) | cfm | |||||||

| SLAD-1MXF | 1.2 | 42 | 24 | G1" | 186 | 812 | 620 | 1417 |

| SLAD-2MXF | 2.5 | 88 | 40 | G1" | 256 | 732 | 586 | 2017 |

| SLAD-3MXF | 3.6 | 127 | 60 | G1" | 341 | 962 | 638 | 1711 |

| SLAD-4.5MXF | 4.8 | 169 | 85 | G1 1/2" | 447 | 842 | 642 | 2225 |

| SLAD-6MXF | 6.8 | 240 | 120 | G1 1/2" | 630 | 950 | 642 | 2105 |

| SLAD-8MXF | 8.5 | 300 | 158 | G2" | 678 | 1288 | 696 | 2231 |

| SLAD-10MXF | 10.9 | 384 | 190 | G2" | 810 | 1288 | 696 | 2331 |

| SLAD-12MXF | 12.8 | 451 | 190 | G2" | 810 | 1288 | 696 | 2331 |

| SLAD-15MXF | 16 | 564 | 310 | DN65 | 983 | 1743 | 735 | 2356 |

| SLAD-20MXF | 22 | 775 | 492 | DN65 | 1271 | 1933 | 736 | 2415 |

| SLAD-25MXF | 26.8 | 945 | 578 | DN80 | 1371 | 1903 | 823 | 2738 |

| SLAD-30MXF | 32 | 1128 | 600 | DN80 | 1550 | 2101 | 913 | 2462 |

| SLAD-40MXF | 43.5 | 1533 | 856 | DN100 | 1994 | 2200 | 1002 | 2576 |

| SLAD-50MXF | 53 | 1868 | 1002 | DN100 | 2127 | 2213 | 1002 | 2594 |

| SLAD-60MXF | 67 | 2361 | 1718 | DN125 | 3243 | 2716 | 1270 | 2857 |

| SLAD-80MXF | 90 | 3172 | 2300 | DN125 | 3698 | 2816 | 1453 | 2911 |

| SLAD-100MXF | 110 | 3877 | 2800 | DN150 | 4677 | 3312 | 1751 | 3094 |

| SLAD-120MXF | 130 | 4582 | 3370 | DN150 | 5140 | 3420 | 1900 | 3159 |

| SLAD-150MXF | 160 | 5639 | 4070 | DN200 | 6126 | 3812 | 1900 | 3378 |

| SLAD-200MXF | 210 | 7402 | 5530 | DN200 | 8370 | 4224 | 2235 | 3534 |

| SLAD-250MXF | 260 | 9164 | 6116 | DN250 | 13100 | 4616 | 2647 | 3805 |

| SLAD-300MXF | 310 | 10926 | 7016 | DN250 | 15000 | 4816 | 2802 | 3883 |

Package and Shipment

● Packing details: Wooden crate pallet plus foam board and bubble film, Full closed wooden case. 1pcs/each package (for stationary desiccant air dryer)

● Transportations: sea transport, rail transport, air transport, road transport, LCL/ FCL container transport or as requested

● Trade terms: FOB, CFR, CIF and EXW, DDP, etc.

● Delivery time: in 20 days after receiving deposit (customized machines not included)

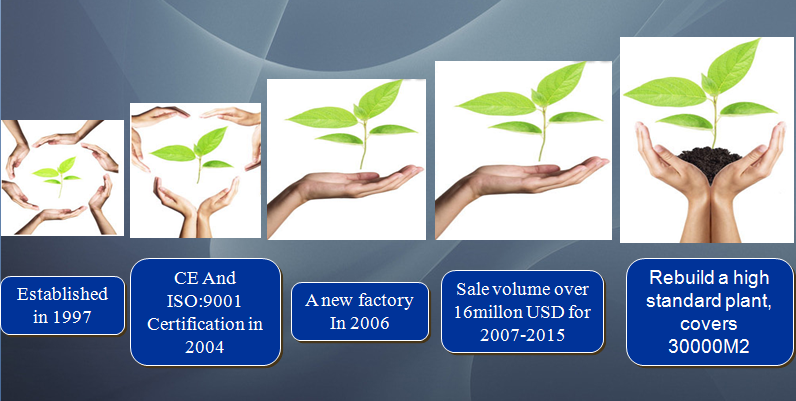

Company Information

● Hangzhou Shanli Purify Equipment Corp., was formed in 1997, as a compressed air solutions company.

● The workshop at integrated engineers and contractors has a dedicated team, which is continuously engaged in upbringing of new technologies for greater efficiency.

● The company was involved in supplying of refrigerated air dryers, desiccant air dryers, compressed air filters, oil water separators and water chillers as a manufacturer, exporter and supplier.

Advantage

1. Quality:

● Certification: CE, ISO-9001, ISO-14001 and 26 patents to ensure unmatched quality of our product assortment.

● Stringent quality control mechanism: updating the involved technology as per prevailing international standards;

● Stable performance: using premium grade raw material from highly reputed manufacturers, like Danfoss, Emerson, Performer, Bitzer, Fusheng, Sprolan;

2. Customer:

● Some of major cooperated customers (from our wide range of customers ) have been enlisted below for reference:

| S.NO. |

VALUED CUSTOMERS |

S.NO. |

VALUED CUSTOMERS |

S.NO. |

VALUED CUSTOMERS |

|---|---|---|---|---|---|

| 1 | Atlas Copco |

2 | BOGE Kompressoren |

3 | Ingersoll Rand |

| 4 | CompAir Air Compressors |

5 | Sinopec Group |

6 | Sullair Asia |

3. Scale:

● Shanli has become one of largest manufacturers in purifying industry of China with annual sales turnover USD 22 million.

● Shanli has a wide range of customers who have full faith in our service delivery, warranty, quality and workmanship.

Product Applications

There are still some areas and applications where Shanli air dryers can be used, such as power construction, packing food, making ship, cleaning medical molding,removing EDM recast and discoloration, finishing and texturing injection mold cavities, cleaning orifices inturbine blades, engraving optical lenses,cleaning and preparation of semi-precious stones and jewelry, etc.

FAQ

Q1: Is it all right to make customer's own brand name?

A:Yes,welcome.

Q2:Are you a manufactuer or trading company?

A:We are manufacturer which become one of the largerst manufacturers in the chinese purification industry.

Q3:Can you do the design for us?

A:Of course.

Q4:Packaging & Shipping:

A:For the package,it's up to the product. Always we packed one product one carton.

For the shipping, by sea or by air is acceptable.

Q5:What about the lead time for mass production?

A:It's up to the order. If we have this product in stock, one week can be delivered.

Q6:What are your main products?

A:Our main product are refrigerated air dryers, desiccant air dryers,combined air dryers, filters and so on.

Q7:What is your terms of delivery?

A:FOB, CIF, CFR all can be accpetable.

Q8:What's your payment term?

A:It's T/T,L/C,D/P and so on.

Q9:When can I get the price?

A:Within a day

Q10:Where is your company?

A:In Hangzhou,China

Q11:Where is your loading port?

A:Shanghai or ningbo port.

Q12:How soon we can get email response from your team?

A:As soon as possible

Q13:If we have some other product requirements that your page don't include, can you help to supply?

A:We can try our best to meet your requirement.

Q14:What's the list of certificates you holds?

A:WSF,CE certificate

Q15:Are you in stock?

A:Yes.

Q16:Does your product have warranty service?

How long is the warranty period?

A:Yes, normally one year warranty.