Search This Supplers Products:Refrigerated air dryerDesiccant air dryerWater chillerHeat recovery systemAdsorption air dryerAir filter

Refridgerated homemade air dryer

- FOB Price

US $600.001 - 1 unit

- group name

- Refrigerated air dryer

- Min Order

- 1 unit

- brand name

- SHANLI

- model

- SLAD-6NF

- Nearest port for product export

- Ningbo, Shanghai, Guangzhou, Tianjin

- Delivery clauses under the trade mode

- FOB, CFR, CIF, EXW, Express Delivery

- Acceptable payment methods

- T/T, L/C, Cash

- update time

- Sat, 14 Feb 2026 17:12:39 GMT

Paramtents

Air inlet temp ≤60°C

Cooling way Air-cooled

Ambient temp ≤50°C

Pressure dew point 2~10°C

Air inlet pressure 0.6~1.6MPa

Heat exchanger plate-fin heat exchanger

Place of origin Hangzhou, China

Capacity 6.5m3/min

Warranty 18 months

Color depend on requirement

Packging & Delivery

- 105cm x64cm x76cm

-

Min Order1 unit

Briefing

Detailed

Product name: Air-cooled refrigerated air dryer

Product model: SLAD-6NF

Product Function

● Dry, quality air is vital for long-term, trouble-free operation of your processes. SHANLI SLAD series dryers protect your products and systems against damage or corrosion.

● They remove moisture from compressed air with a dew point as low as 2-10 °C/35.6-50 °F. Easy to install, simple to operate and reliable, they provide the dry air you need, allowing you to concentrate on your core business.

Technical Specifications

● Pressure range: 0.6-1.6 Mpa

● Max air inlet temp.: 60 Deg C

● Max ambient temp.: 50 Deg C

● Cooling method: air cooled type / water-cooled type

● Pressure dew point: 5 Deg C

● Power: 220/380V-1PH-50HZ

● Refrigerant: R-22 (R-407C, R-134A as optional)

Note: Refrigerated air dryer without metal box board for over 80 m3/ min. Other special standards can be customized.

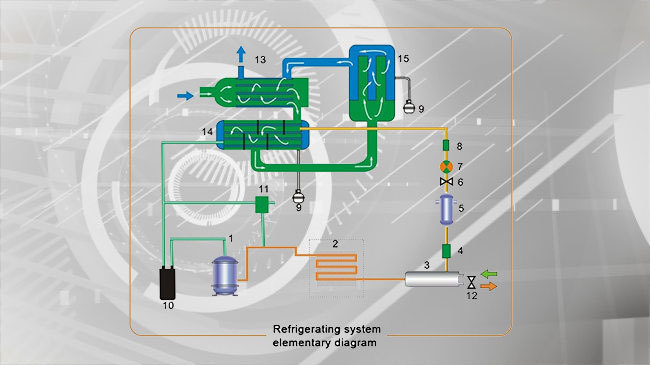

Working Principle

Refrigeration compressed air dryer makes the water vapor in the compressed air condenses into droplets through cooling so as to achieve the purpose of reducing moisture content. Condensed droplets are discharged by the automatic drainage system.

Annotation:

| 1. Cooling medium compressor | 6. Manual valve | 11. Hot gas by-pass valve |

|---|---|---|

| 2. Air condenser | 7. Cooling medium sight glass | 12. Water volume adjustable valve |

| 3. Water condenser | 8. Expansion valve | 13. Pre-cooling gas |

| 4. Magnetic valve | 9. Automatic drainer | 14. Evaporator |

| 5. Drying filter | 10. Gas water separator | 15. Effective separator |

Performance Parameters

| Refrigerated Compressed Air Dryer | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Model | Flow Capacity (Nm3/min) | Voltage (V) | Fan Power (W) | Pipe Diameter | Air Inlet Pressure (Mpa) | Net Weight (Kg) | Length (mm) | Width (mm) | Height (mm) | Air Flow (N3/h) |

| SLAD-0.5NF | 0.65 | 220 | 1x67 | G1/2" | 0.6-1.0 MPa | 45 | 750 | 430 | 610 | 760 |

| SLAD-1NF | 1.2 | 220 | 1x67 | G1" | 70 | 780 | 450 | 610 | 760 | |

| SLAD-2NF | 2.5 | 220 | 1x95 | G1" | 110 | 800 | 460 | 720 | 1580 | |

| SLAD-3NF | 3.6 | 220 | 1x150 | G1" | 130 | 950 | 480 | 720 | 3150 | |

| SLAD-4.5NF | 5 | 220 | 1x240 | G1 1/2" | 150 | 1170 | 540 | 750 | 5580 | |

| SLAD-6NF | 6.8 | 220 | 2x150 | G1 1/2" | 160 | 1350 | 520 | 753 | 6300 | |

| SLAD-8NF | 8.5 | 220 | 2x195 | G2" | 200 | 1100 | 670 | 1098 | 8470 | |

| SLAD-10NF | 10.9 | 380 | 2x195 | G2" | 250 | 1200 | 670 | 1098 | 8470 | |

| SLAD-12NF | 12.8 | 380 | 2x195 | G2" | 300 | 1200 | 670 | 1048 | 8470 | |

| SLAD-15NF | 16 | 380 | 2x190 | DN65 | 320 | 1460 | 750 | 1630 | 8470 | |

| SLAD-20NF | 22 | 380 | 2x240 | DN65 | 420 | 1670 | 800 | 1663 | 11160 | |

| SLAD-25NF | 26.8 | 380 | 2x240 | DN80 | 550 | 1820 | 800 | 1713 | 11160 | |

| SLAD-30NF | 32 | 380 | 2x380 | DN80 | 650 | 1900 | 860 | 1875 | 15240 | |

| SLAD-40NF | 43.5 | 380 | 3x240 | DN100 | 2200 | 2200 | 930 | 1941 | 16740 | |

| SLAD-50NF | 53 | 380 | 3x380 | DN100 | 2450 | 2450 | 900 | 2110 | 22860 | |

| SLAD-60NF | 67 | 380 | 4x380 | DN125 | 2140 | 2140 | 1450 | 1787 | 30480 | |

| SLAD-80NF | 90 | 380 | 4x550 | DN125 | 2070 | 2070 | 1600 | 2029 | 42400 |

cools the refrigerant slightly so that it changes from gas to

liquid; refrigerant is more effective in the liquid state.

7 Capillary filter

protects the expansion device from harmful particles.

8 Capillary tube

reduces the refrigerant’s pressure, thereby lowering its

temperature and increasing its cooling capacity; the

refrigerant is now almost all liquid, with some residual gas.

9 Hot gass bypass

regulates the amount of refrigerant passing through

the air-to-refrigerant heat exchanger, ensuring a stable

pressure dewpoint, and eliminating the chance of the

condensate freezing.

Refrigerant circuit

10 Air inlet

hot saturated air enters the dryer and is cooled by the

outgoing air via the air-to-air heat exchanger. Reducing

the temperature of the inlet air reduces the load on the

refrigerant circuit.

11 Air-to-refrigerant heat exchanger

transfers heat from the compressed air to the cold

refrigerant, forcing water vapour in the compressed air to

condense. The more effective the heat transfer, the cooler

the air becomes and the more water vapour condenses.

12 Air/ air heat exchanger

13 Water separator

collects and drains off condensate from the cooled air flow.

The more efficient the separation, the better the pressure

dewpoint, as droplets which are not collected revapourise

and degrade the pressure dewpoint. The collected droplets

are reliably evacuated from the separator through an

electronic drain.

14 Automatic drain

15 Air outlet

re-heats the outgoing air to prevent condensation

on the factory’s pipework

Email:jovelyzou..........com

website: ..........com